In the field of engineering materials and decoration, "Which is stronger, Acrylic or Plexiglass?" is a frequently asked question. In fact, this problem stems from a cognitive misunderstanding - Plexiglass is the trademark of a well-known brand Acrylic, and due to its great market influence, it has gradually become a synonym for similar products. Both have the chemical composition of polymethyl methacrylate (PMMA), and their physical properties are exactly the same, with no difference in strength. The core of this article is not to compare the two, but to deeply analyze the strength advantages and application logic of Acrylic as a high-quality material.

Name Origin: The "Strength Community" of the Same Origin

Acrylic is the general scientific name for polymethyl methacrylate, covering all similar polymer materials. Plexiglass was a Acrylic product brand launched by an American enterprise in the 1930s. Due to its early leading technology, it became a "synonym" among consumers. From the perspective of industry standards, whether it is the general product marked "Acrylic" or the brand product marked "Plexiglass", their strength indicators all follow the unified specifications of PMMA materials, and the core data such as impact resistance and tensile strength are completely overlapped. Only by clarifying this relationship can we accurately recognize the strength value of Acrylic.

Strength advantage of Acrylic: Its multi-dimensional performance far surpasses that of traditional materials

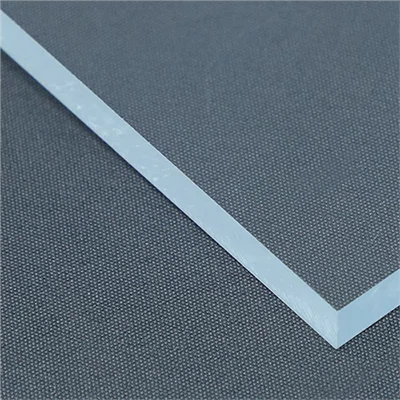

The "strength" of Acrylic is reflected in the balance of comprehensive performance. Impact strength is its most prominent feature - the value can reach 15-20kJ/m², which is 10-15 times that of ordinary glass. When subjected to external impact, it is not easy to shatter. Even if it breaks, it is in the form of particles without sharp edges or corners, and its safety far exceeds that of glass. In terms of tensile strength, Acrylic can reach 60MPa, which can stably withstand daily compression and load, and is suitable for simple structure support scenarios. More importantly, its strength is less affected by the environment. It performs stably within the temperature range of -40℃ to 80℃. After anti-ultraviolet aging treatment, it will not become brittle due to weathering even after long-term outdoor use, and the strength attenuation rate is less than 5%.

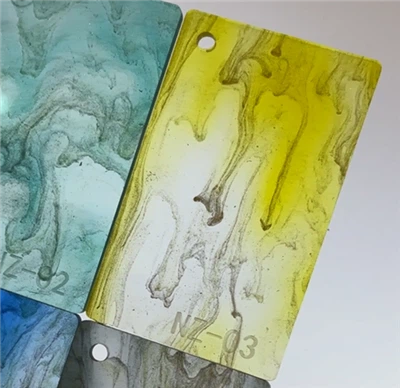

Strength Implementation: Acrylic adapt to diverse scenarios with strength

The strength advantage of Acrylic has deeply permeated various industries. In the field of architecture, it replaces glass for skylights and high-altitude partitions, meeting the requirements of wind resistance and pressure resistance while reducing the risks of installation and maintenance. Large outdoor light boxes and ultra-wide signs in the advertising industry rely on their impact resistance and weather resistance to achieve long-term stable use. In industrial Settings, equipment protective covers and instrument panels made of Acrylic can resist mechanical collisions and chemical corrosion, ensuring production safety. Even for tabletops and partitions in home decoration, their strength can withstand daily wear and tear, taking into account both aesthetics and durability. These application scenarios are essentially concrete manifestations of the strength characteristics of Acrylic.